Overview

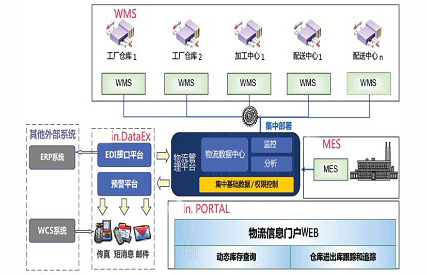

Painting is a material protection technique that uses a high velocity particle stream of molten metal to spray on the surface of the substrate to create a coating. In the process of painting, the paint exhaust gas is generated, which is mainly composed of solid paint residue, liquid paint mist and gaseous VOCs. According to the concentration of organic waste gas and the amount of air, it is treated by spraying, filtering, adsorption (activated carbon adsorption or zeolite wheel adsorption), combustion (CO, RCO, RTO) and other processes.

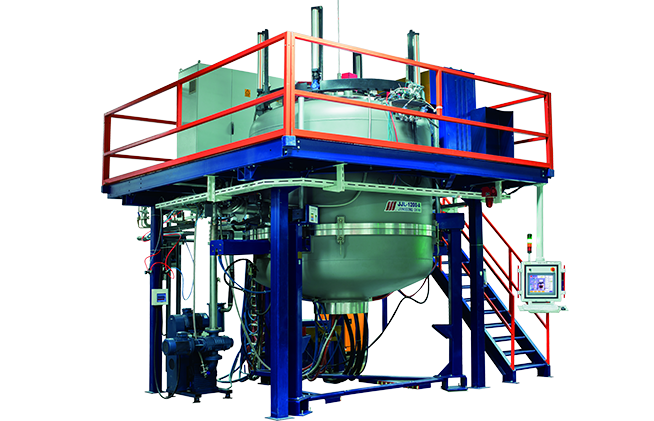

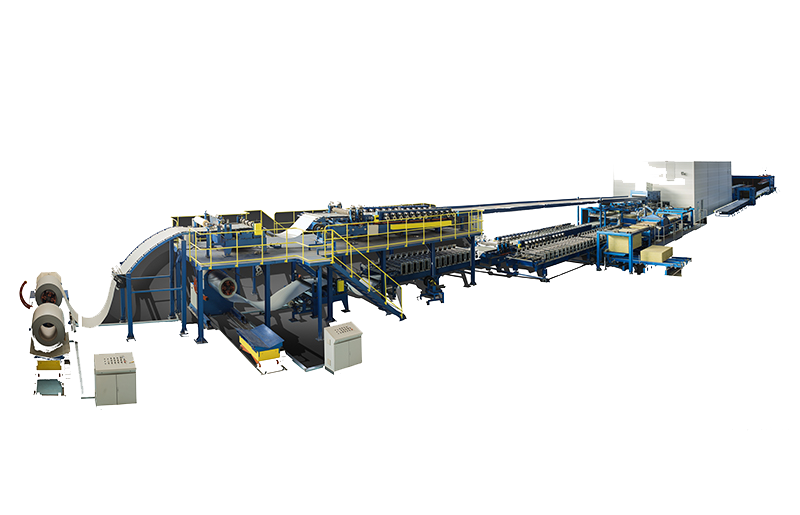

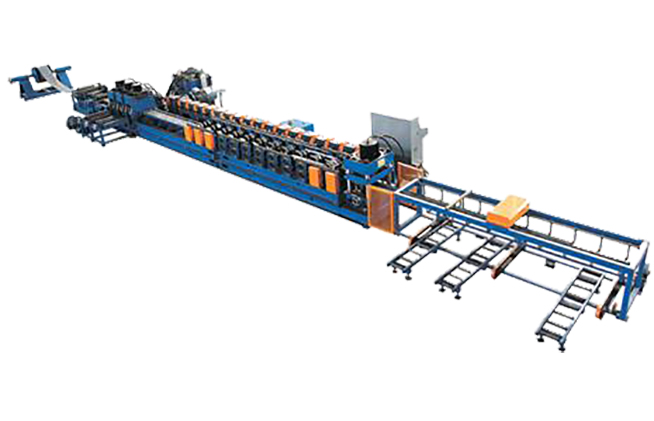

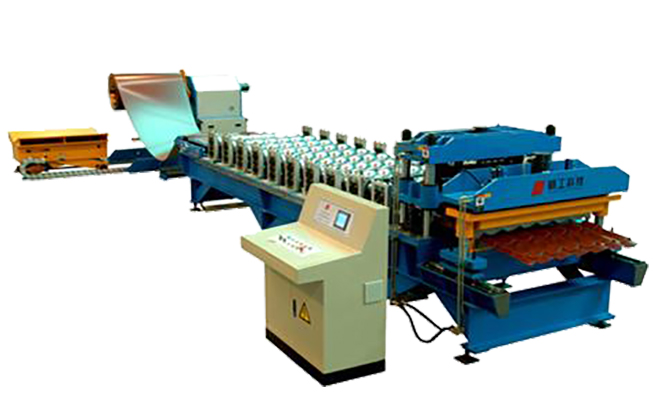

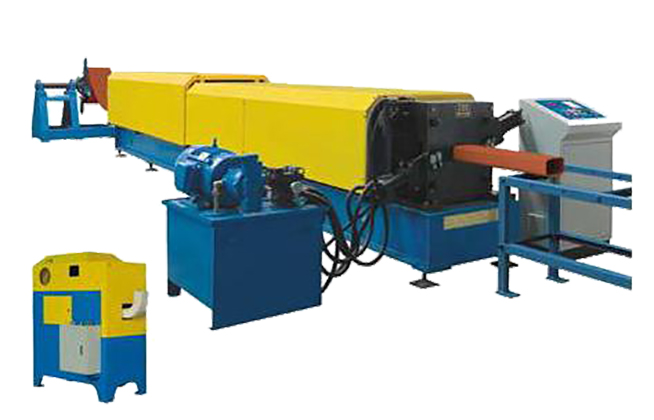

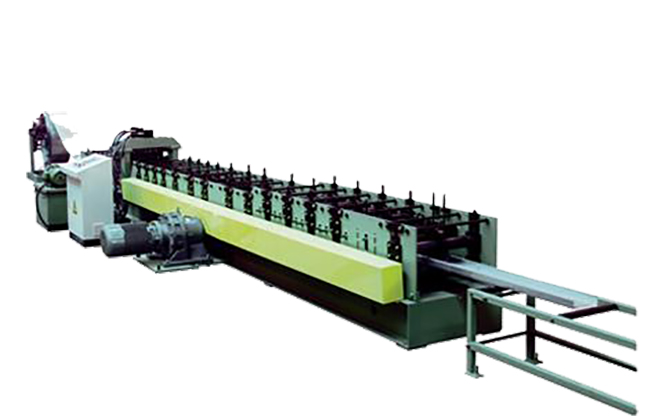

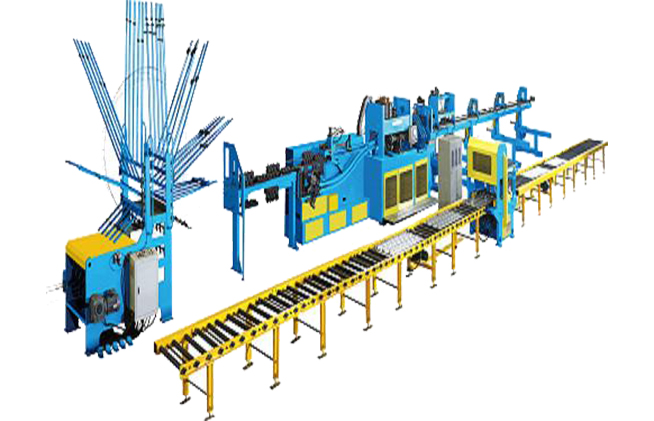

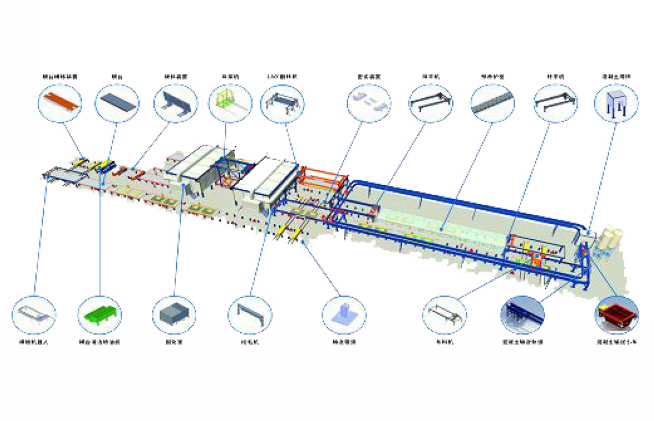

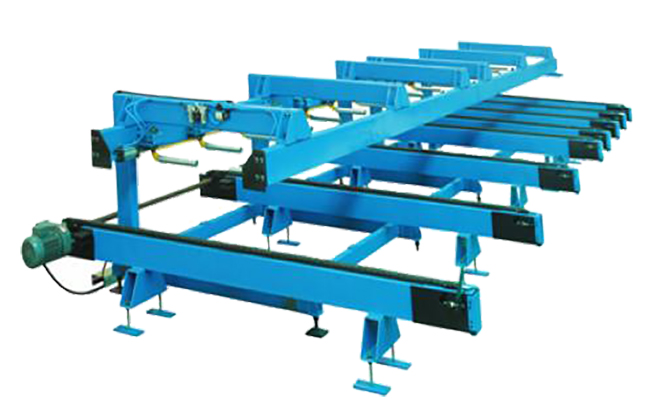

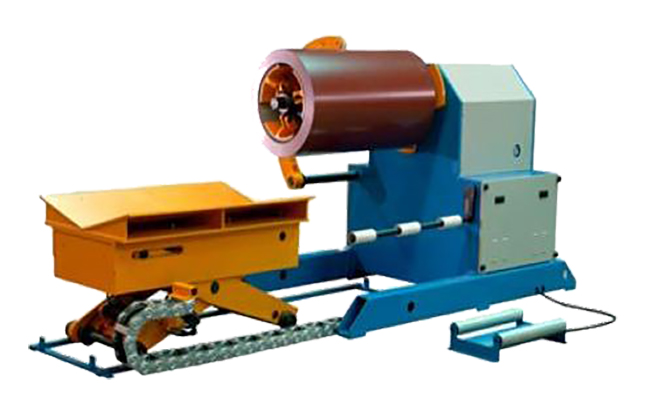

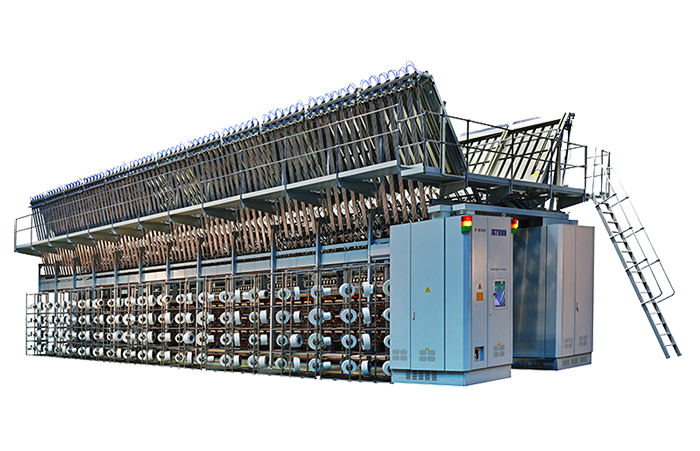

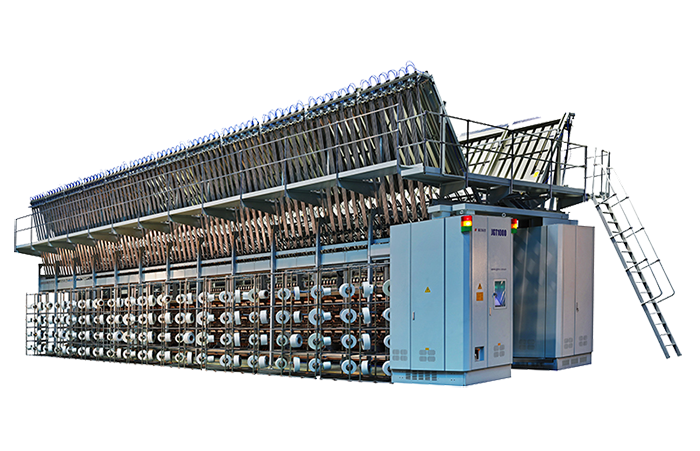

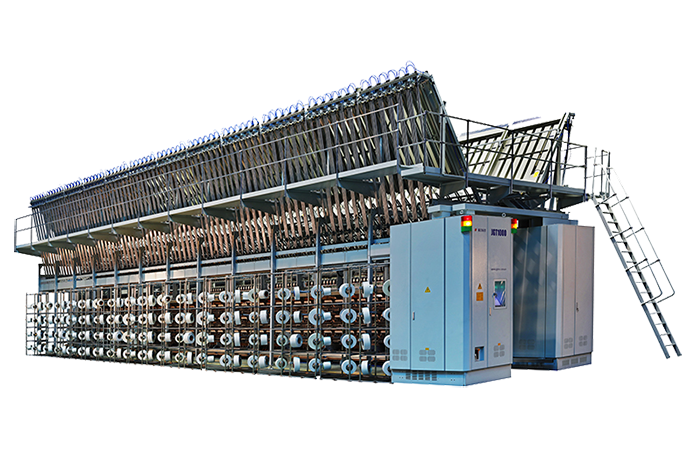

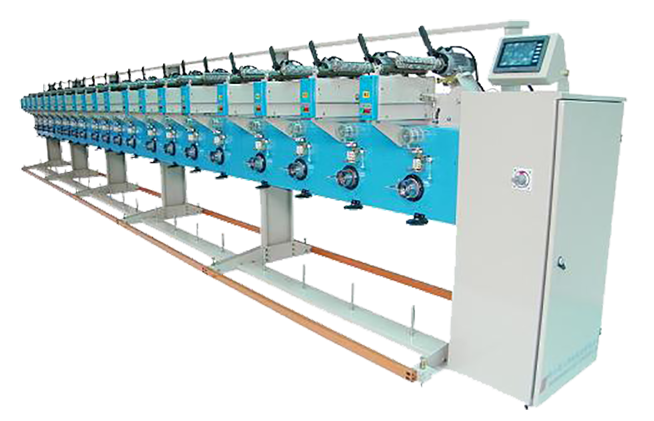

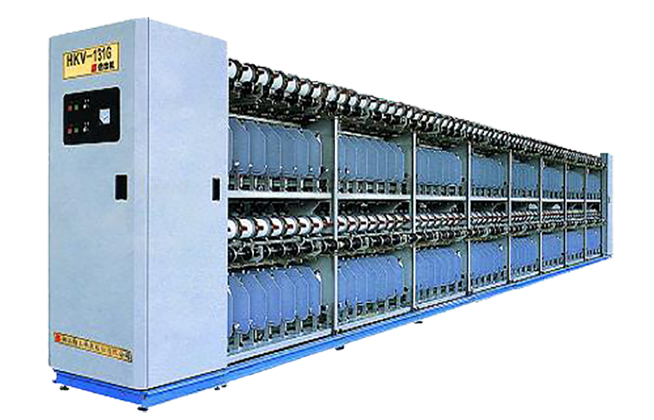

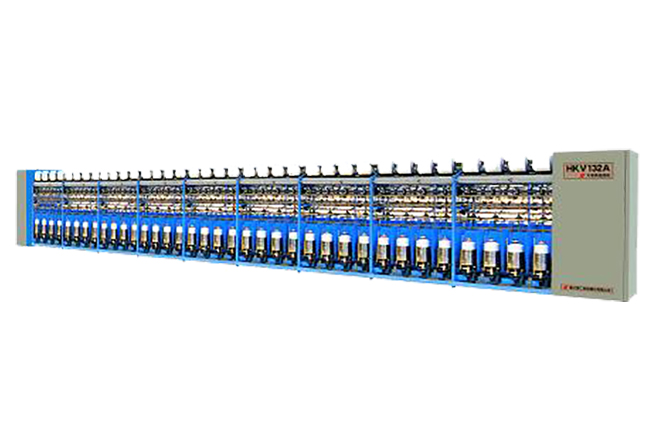

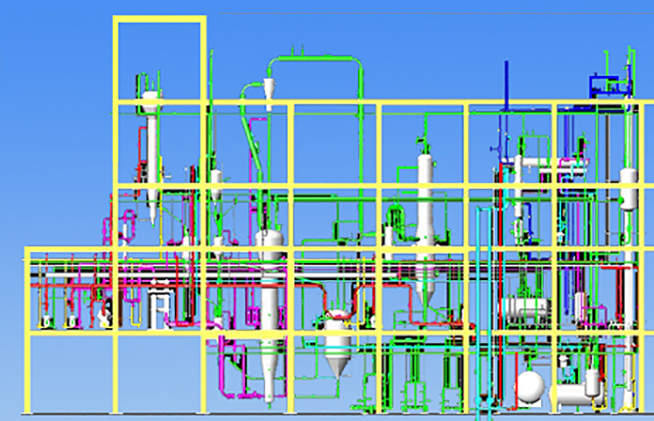

The classic process route adopts “+ dry type + adsorption concentration + combustion catalytic combustion”, the exhaust gas is pretreated to remove the paint powder and organic solvent, the exhaust gas enters the activated carbon adsorption concentration, and the organic waste gas can be concentrated and increased to a dozen times (the activated carbon adsorption tank adsorption saturation) The system can be automatically switched), the hot gas flow is desorbed and desorbed by the activated carbon, and the concentrated exhaust gas is sent to the catalytic combustion chamber (when the exhaust gas reaches 2000 ppm, the catalyst bed can maintain self-ignition without external heating). The equipment is as follows:

Process characteristics

(1) Pre-treatment equipment removes paint residue and paint mist to avoid the problem of subsequent equipment blockage;

(2) The adsorption equipment converts low-concentration, high-volume exhaust gas into high-concentration and small-volume exhaust gas, reducing subsequent equipment specifications and reducing operating costs;

(3) The treatment efficiency of the combustion process exhaust gas reaches more than 95%;

(4) Meet the national environmental emission requirements.

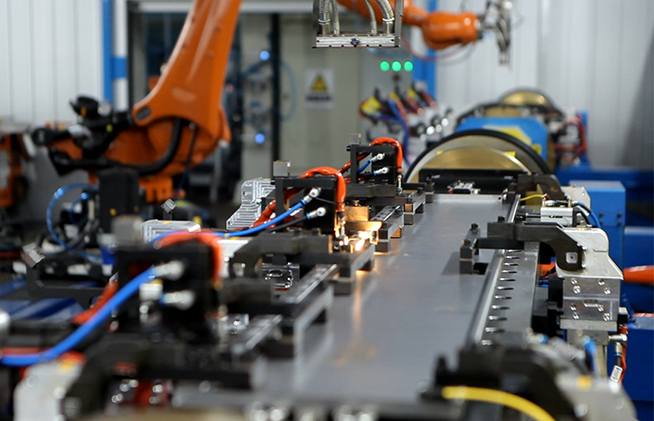

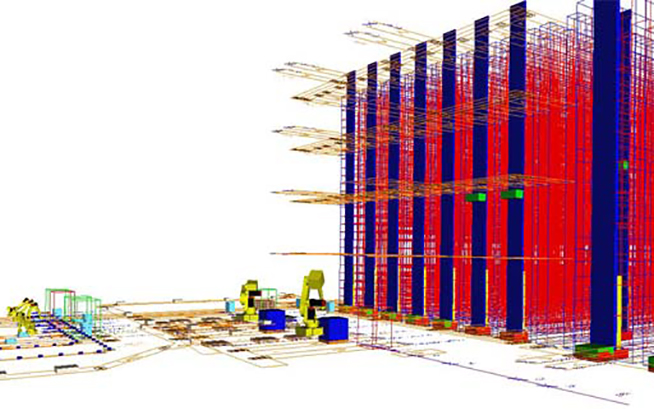

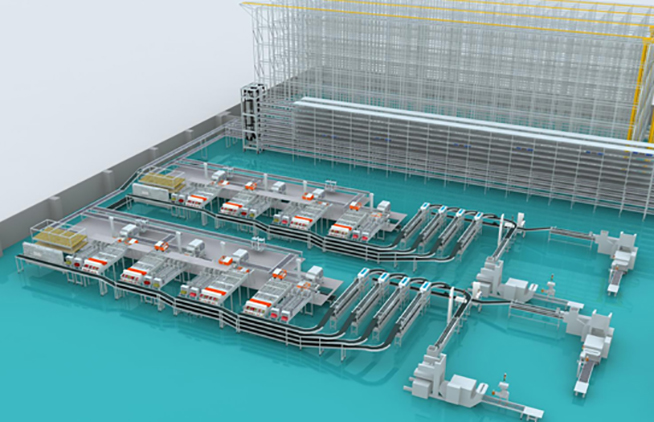

Engineering case