1、EQUIPMENT USE

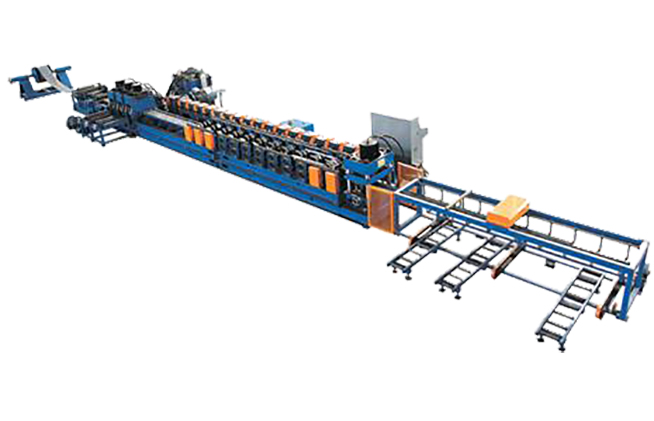

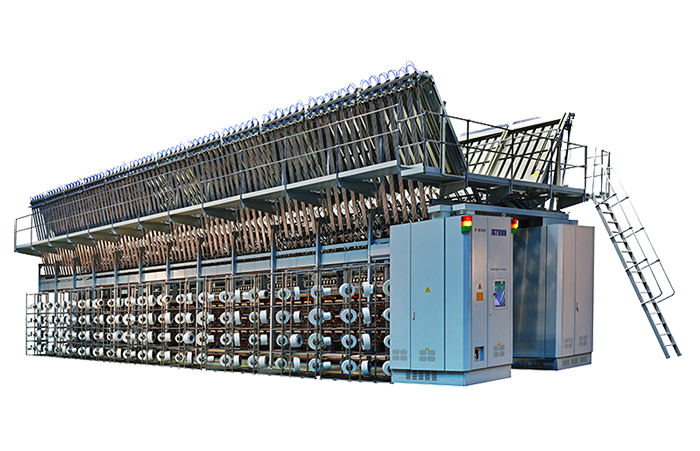

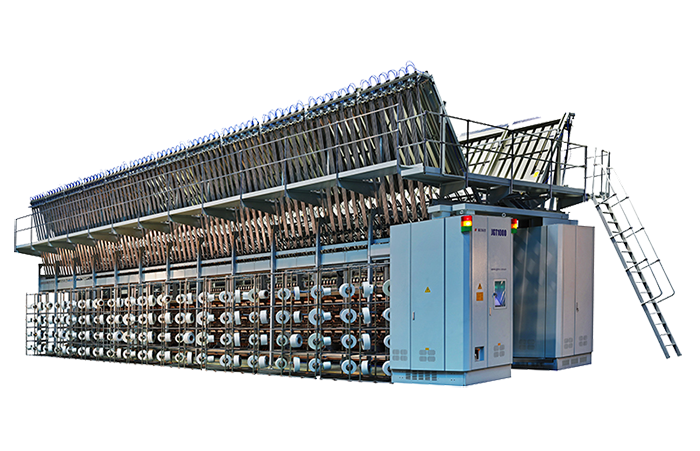

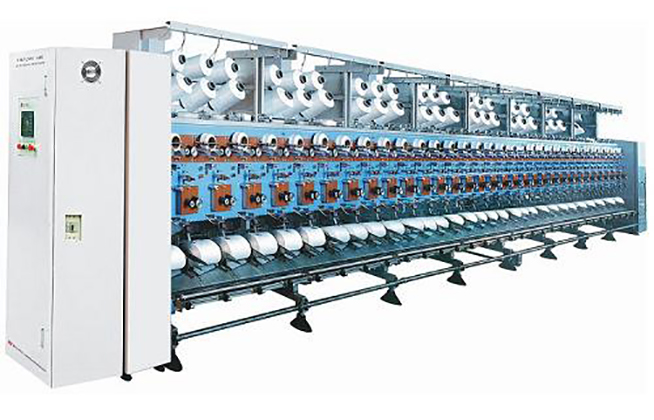

HKV141H type covering machine for metallic yarn is used to produce MX and MH type metallic yarn. It adopts the purl as the core yarn. The outside covering yarn can be nylon or polyester with different specifications according to customer’s requirement. Also , to meet the requirement for processing different product, the purl feeding device of the machine will be active feeding or passive feeding. MX/MH metallic yarn will be widely used in the knitting and weaving field.

2、PRODUCT FEATURES

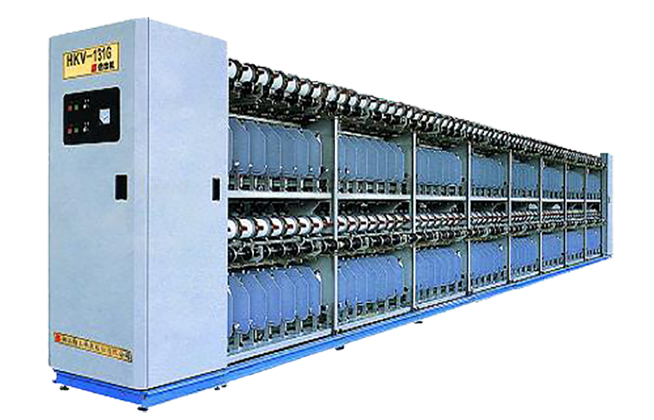

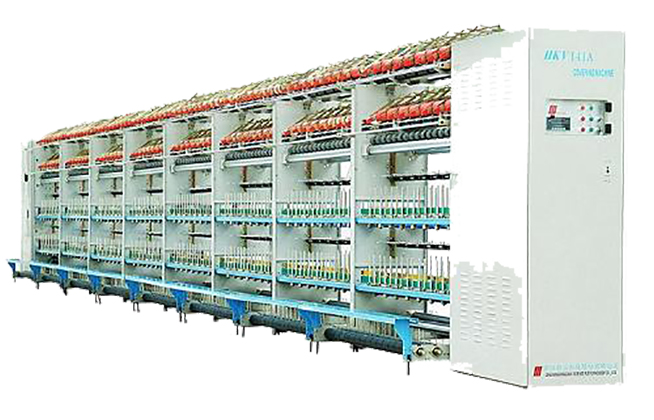

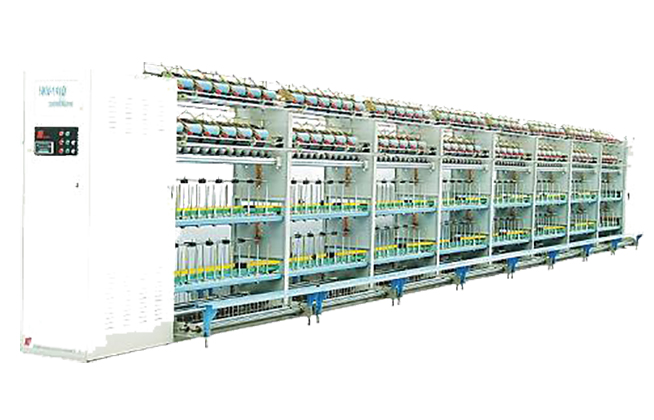

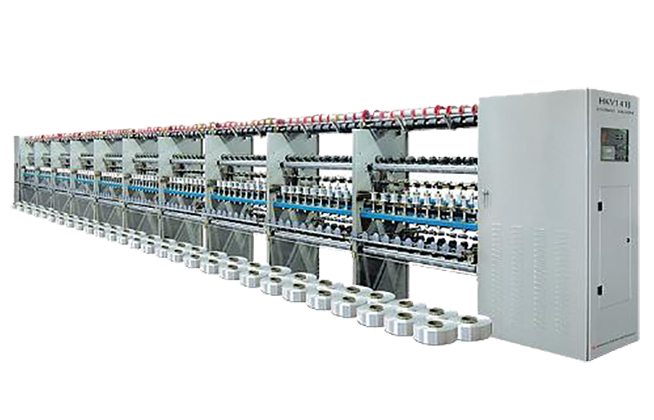

This type of the equipment to specific processing MX and MH type yarn, spindle parts are straight and taper two specifications for user to choose.

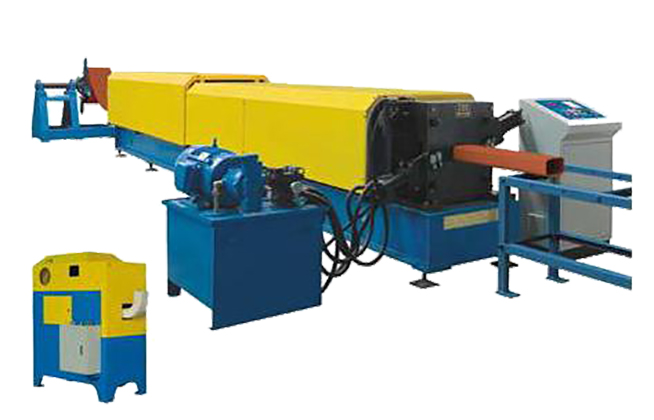

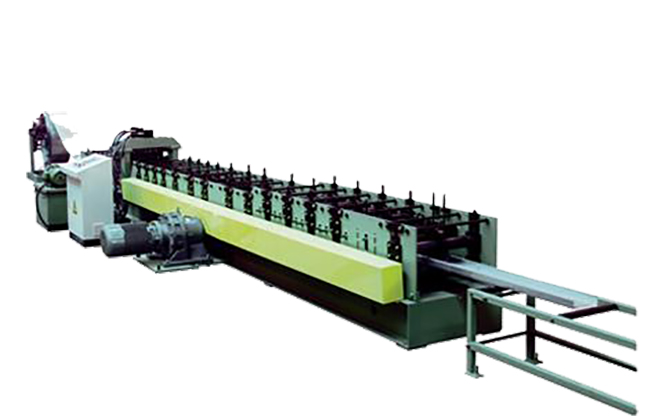

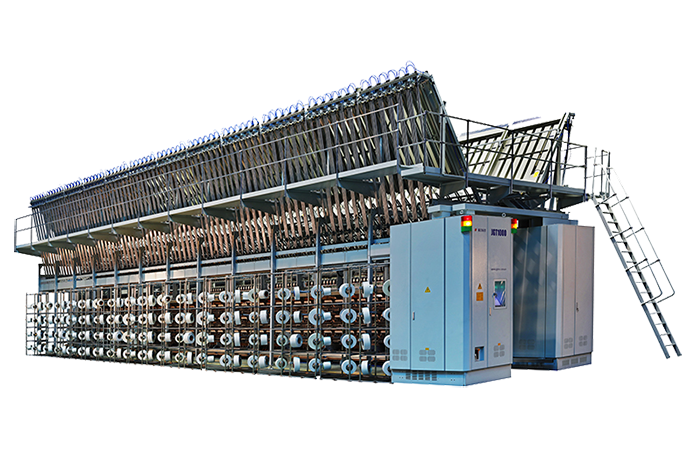

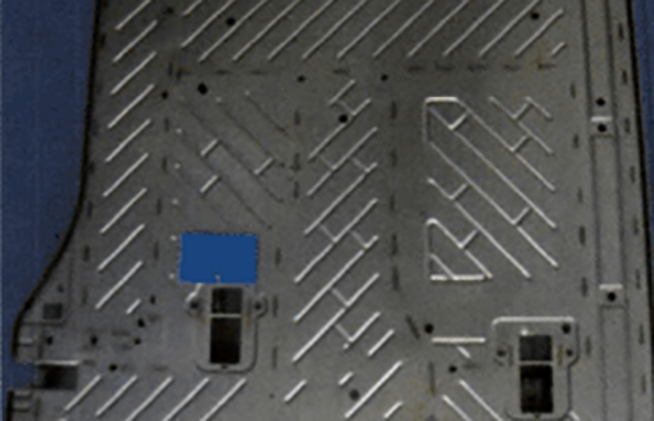

The machine frame for whole steel plate welded, stable, solid, each section32spindles, spindle adopts linear arrangement, it is divided into two layers up and down according to the needs of users, that can produce the MX type yarn, also can produce MH type of yarn, easy to adjust, simple operation.

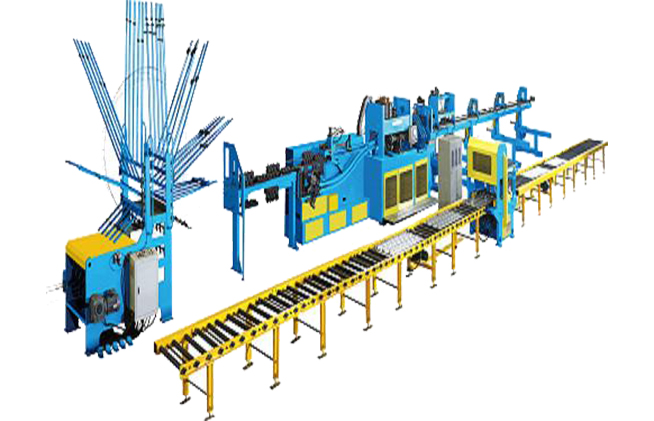

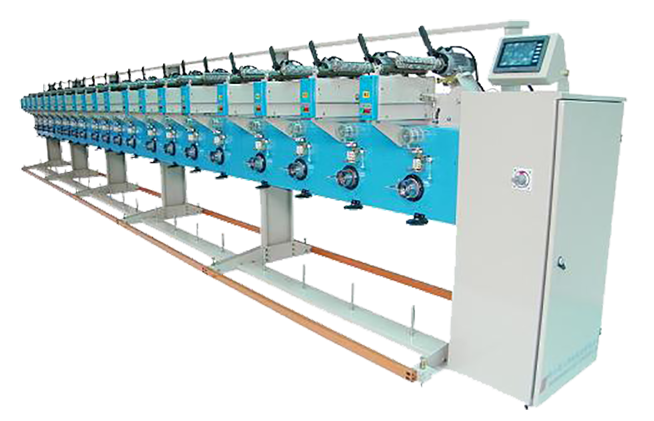

The machine can be option the computer forming system, this system will take fast taking up speed, and yarn forming will become better, and esay to rewinding.

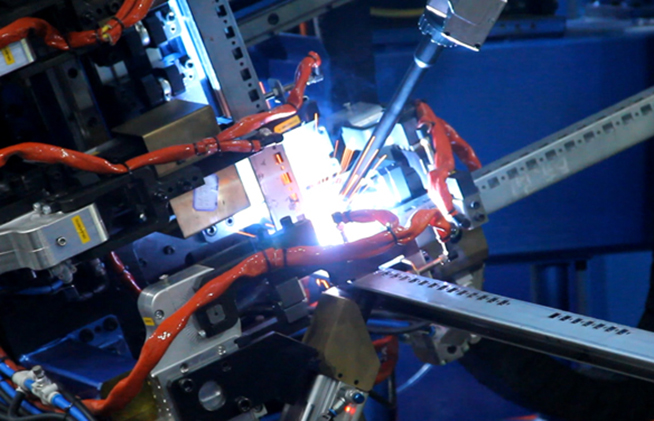

It adopts advanced electric components such as digital control device, which can monitor the operating data of equipment in real time, also it is equipped with motor overheated protection device, double protection motor, which can ensure the safety both of people and machine.

This machine is suitable for a variety of different specifications of the metallic yarn covering, the adoption of advanced axial and circumferential folding mechanism, and progressive as device, it easy to the unwinding of next working procedure.

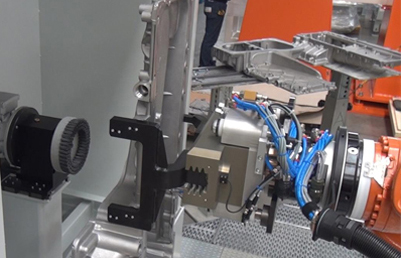

According to different work flow and specification, user can choose reasonable pinch wheel type, user can choose manual type or swing arm type pinch wheel, which can meet the processing requirement of different yarns.

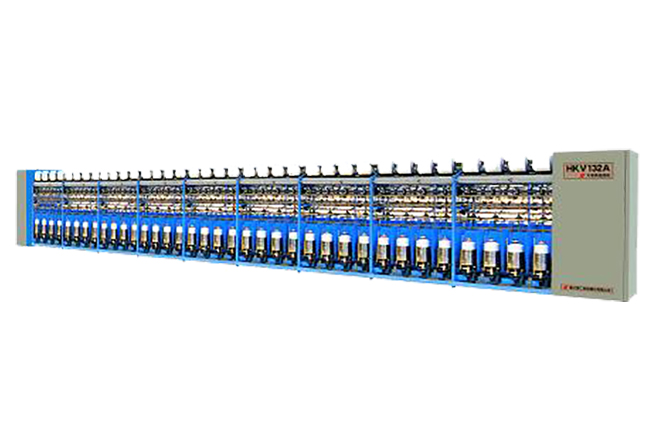

In the Spindle plate below, tensioner part of metallic yarn. Effectively ensure the core yarn (metallic yarn) uniform tension when feeding, to ensure products without distortion.

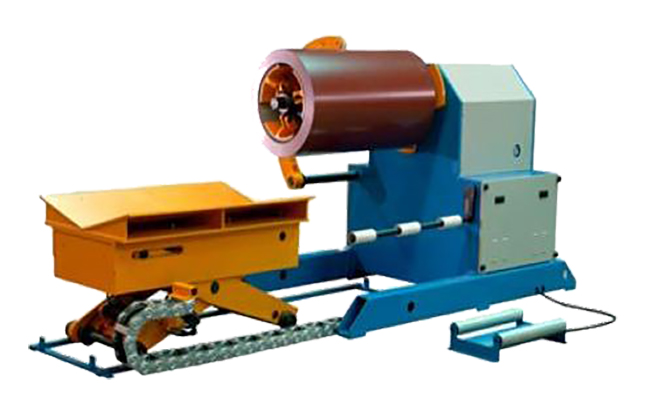

On the lower end of the machine, equipped with positive type metallic yarn feed into the device and passive metallic yarn feeding device, according to the requirements of different raw materials and process, the user can select an agency to meet the production.

The machine head there are two motors, drives the upper and lower two layers of spindle, so that we can fast, S,Z twist transformation is implemented, especially in the double covering MX , it can replace the belt ( or inverter) adjusting the spindle speed, at the same time to ensure that inner and outer yarn torsion balance.

On both sides of the machine, add foot plate, can at any time convenient winding bobbin installation and reduce the operating height, it is more convenient than the machine back and forth cycle, can improve the work efficiency.

3、THE USER CAN SELECT PARTS

Main motor inverter: easy adjustment of spindle speed, simple and accurate

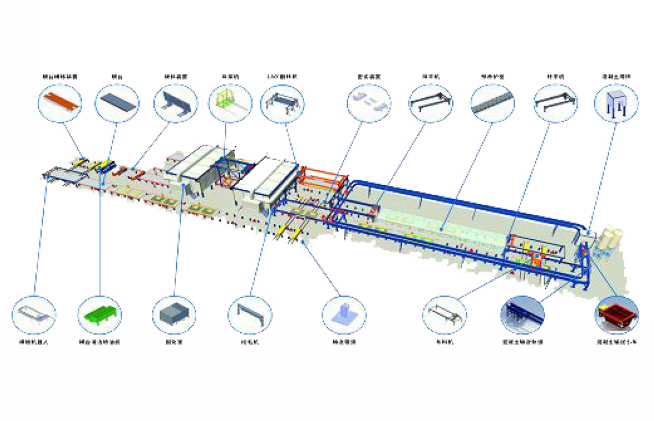

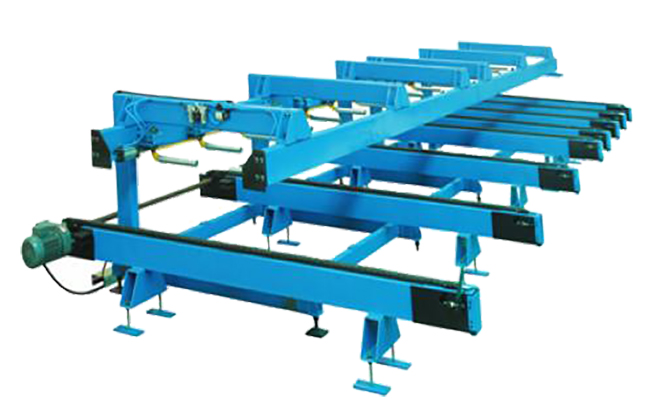

4、DIMENSION AND FOUNDATION DRAWING OF POURING REQUIREMENTS