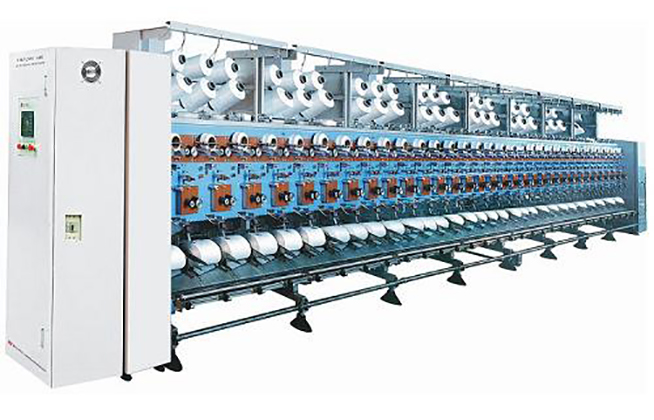

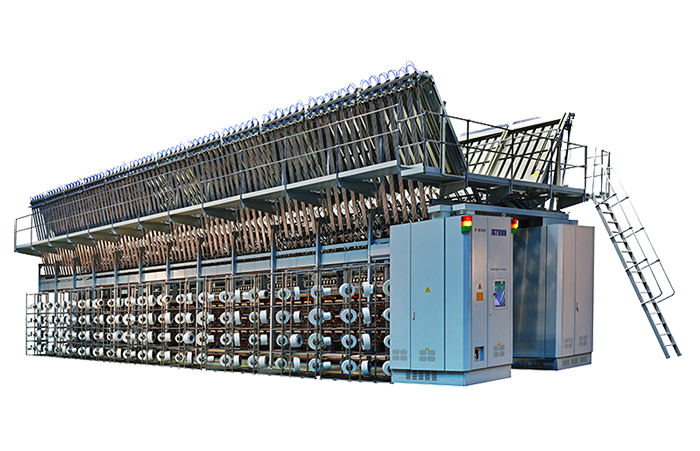

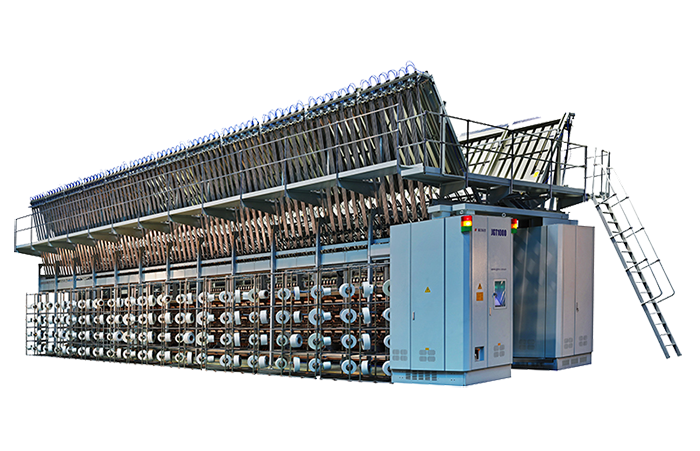

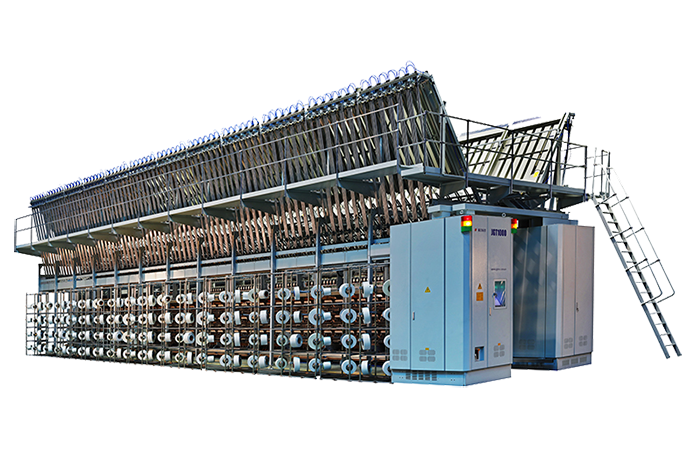

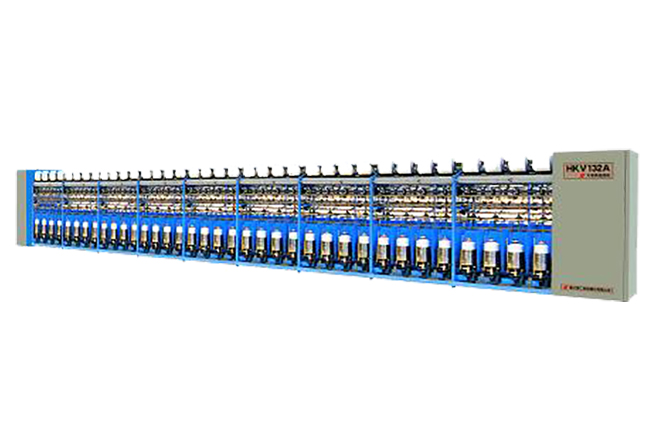

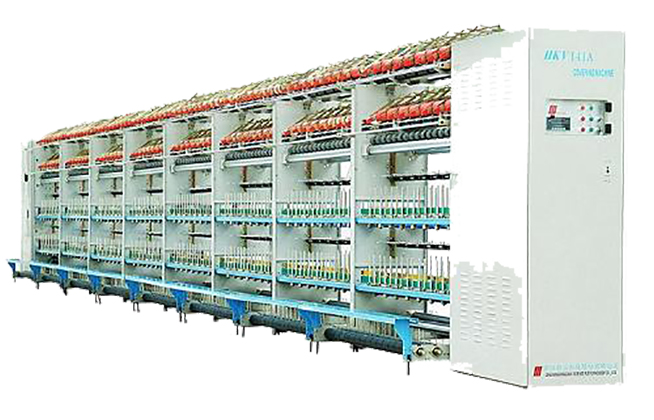

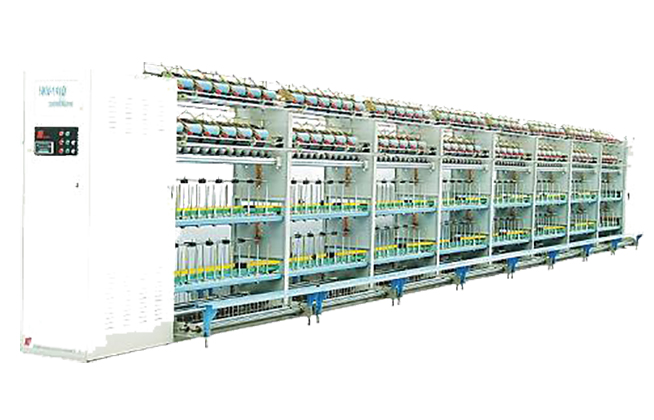

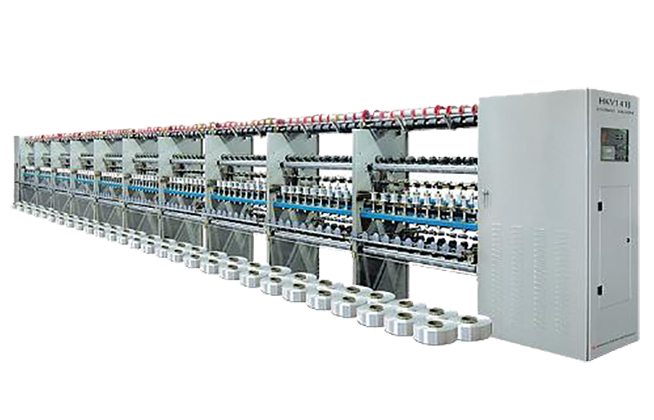

1、Equipment Overview

HKV204 air covering machine mainly produce air covering yarn or meshwork with nylon, polyester and spandex. Its finished product is covering yarn , it is widely used in knitting and shuttle weaving, such as seamless underwear, casual clothing, swimming cloth, knitting socket industrial cloth and so on.

2、PRODUCT FEATURE

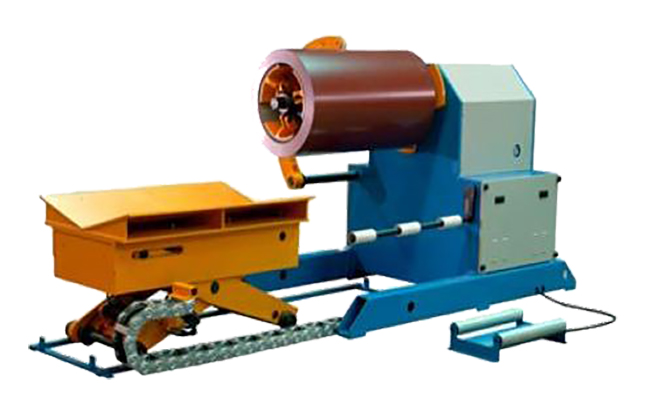

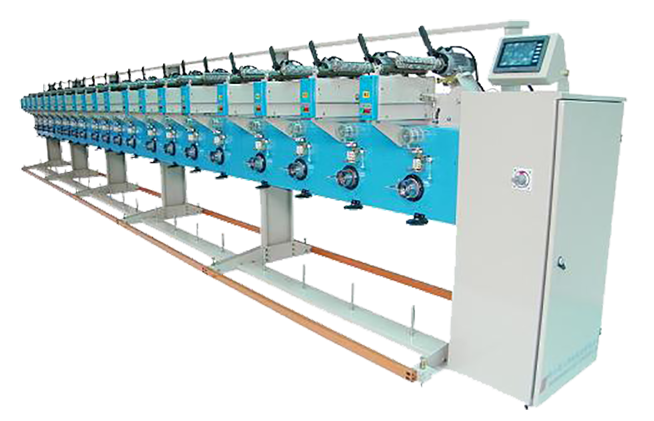

The take-up forming of this machine adopts machine electric integrity control technical,precision control stray, good forming and with fastun reel speed . Unreel tube length has 230mm and 290 mm for option

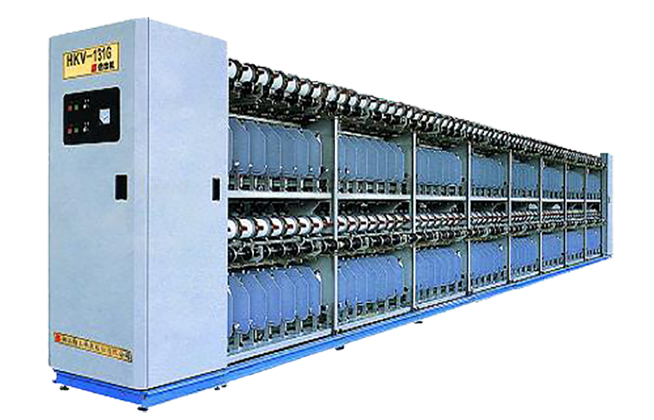

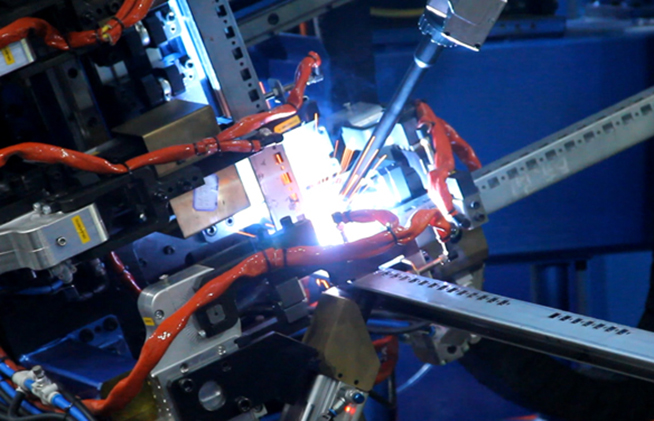

Adopts world top Switzerland Heberlein nozzle, which could ensure good net quality, according to the different yarn specification to choose the nozzle

The machine adopts touch screen panel, the all movement of the all parts, it is only required to set the number, so it is more intelligentize Working setting.

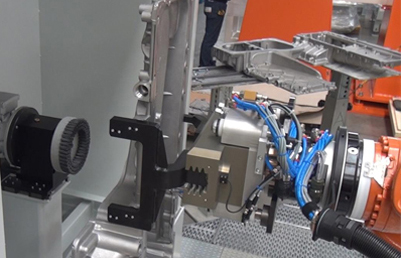

Middle Part Control: it use single spindl econtrol electric board, it has function of control all the single spindle separately, also it can control relevant movement of the yarn detecting device,cutting blade, roller motor

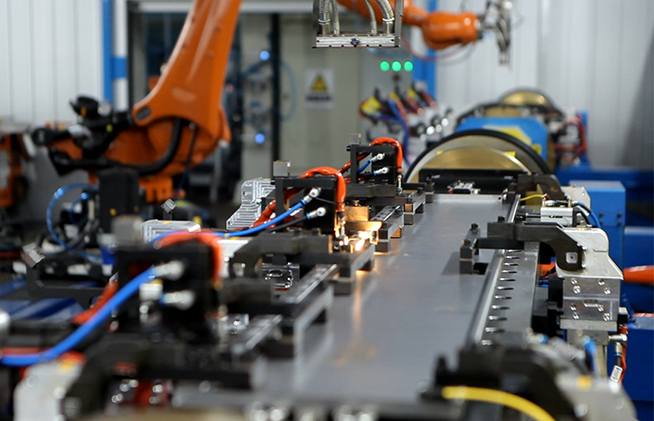

The general control part is installed inside of machine head control box, by all kinds of components, so that it can control all the operation of machine parts, it adopts transducer to adjust the speed, it saves power, the speed is accuracy and stable

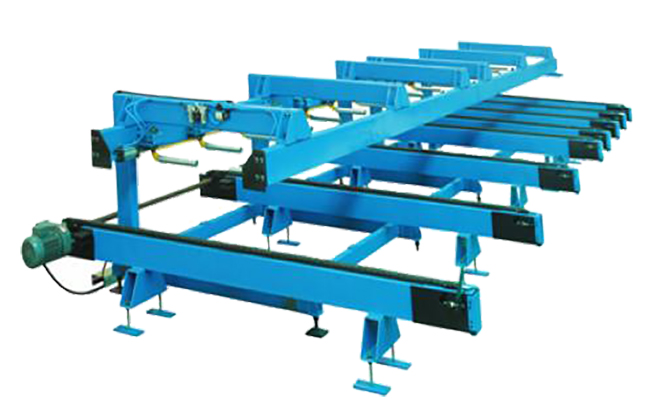

To ensure the take-up forming, it is set with middle collective control electric stray framework. This frame adopts transducer stepless control, according to user’s set parameters , control the forward/backward and operation,stop time by PLC, so that can control the unreel length, so that can realize the function of stray.

It has oil and water separating parts at the gas input mouth, so that can filter the water and oil in compress air, so that can ensure the quality of yarn.

At each spindle position, it has 3 sets of yarn detecting device, and 1 piece of yarn cutting device, when the detecting device detect the yarn is heading off, the middle single spindle control panel will send the signal to the yarn cutting device , cutting the remained yarn, and stop this spindle

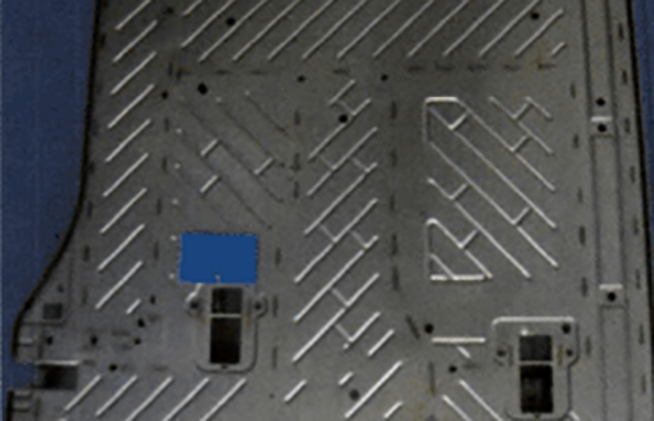

3、DIMENSION AND FOUNDATION DRAWING

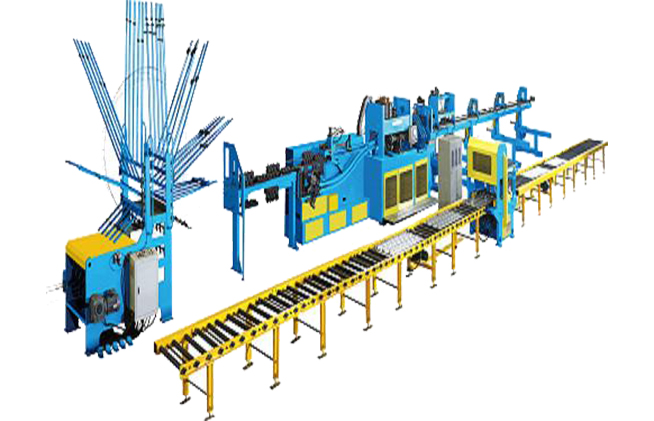

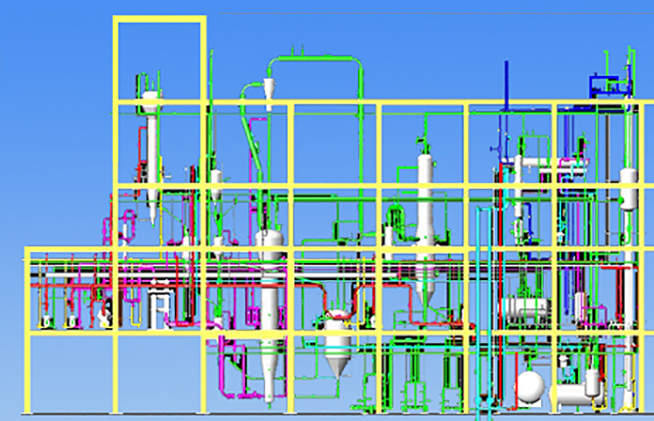

五、压缩空气站配置流程示意图(参考)