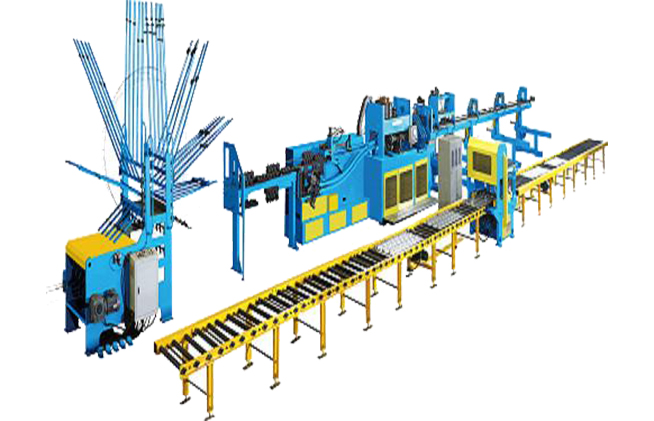

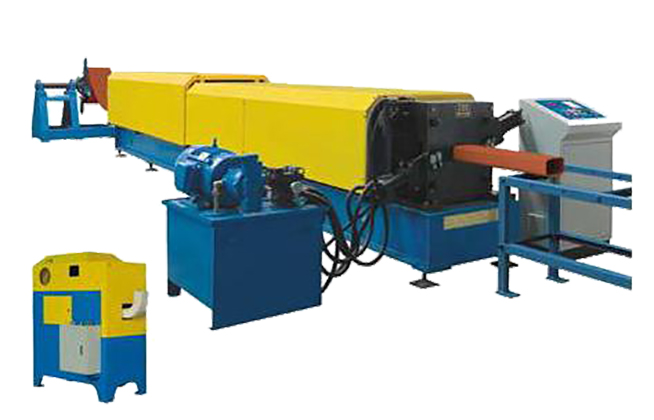

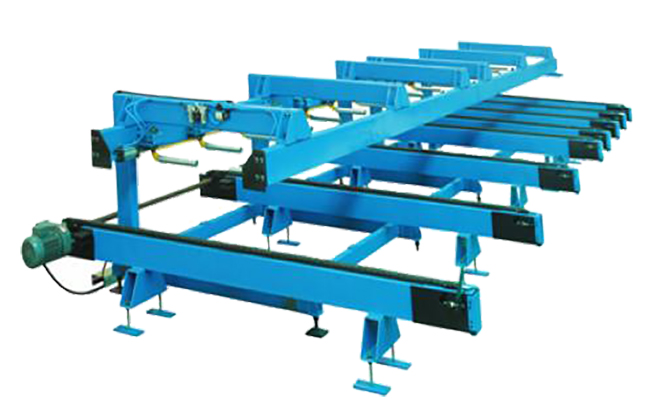

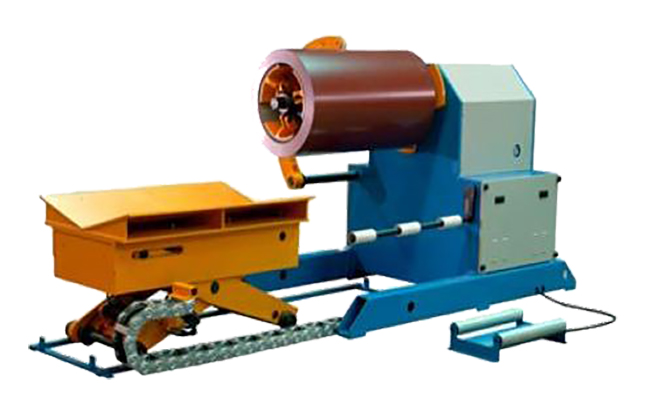

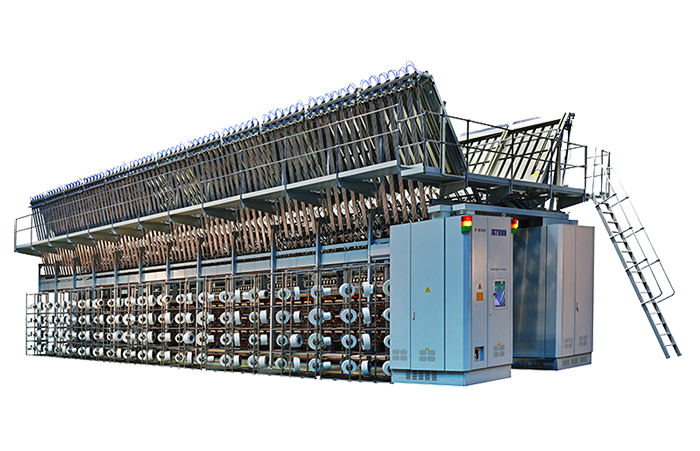

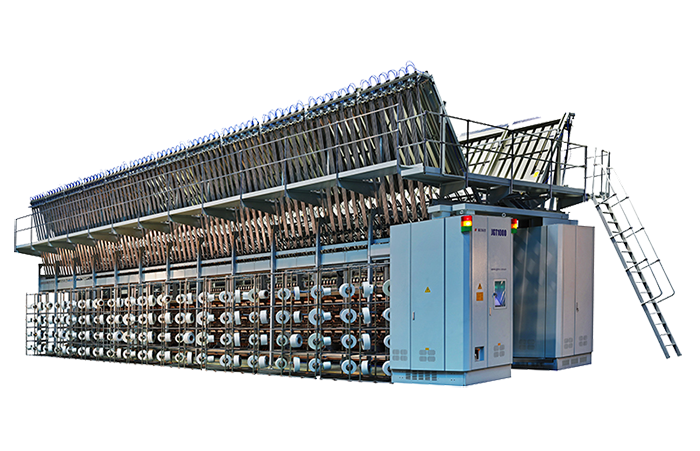

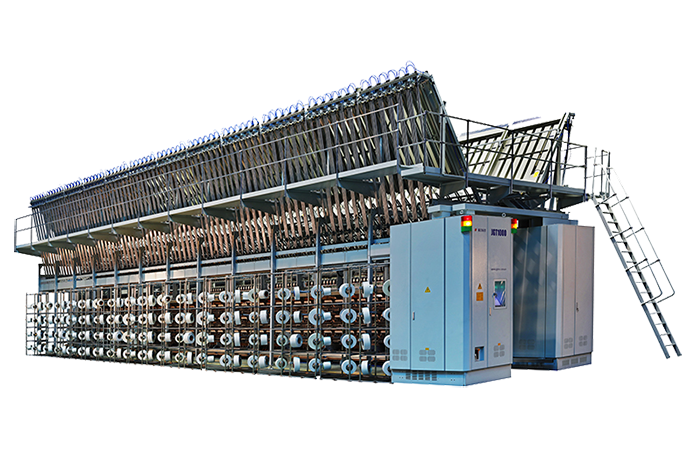

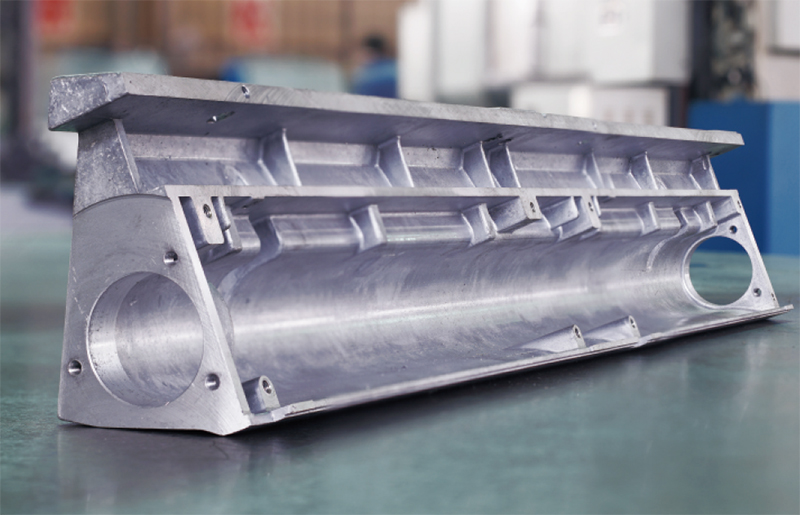

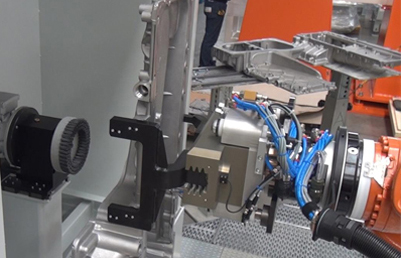

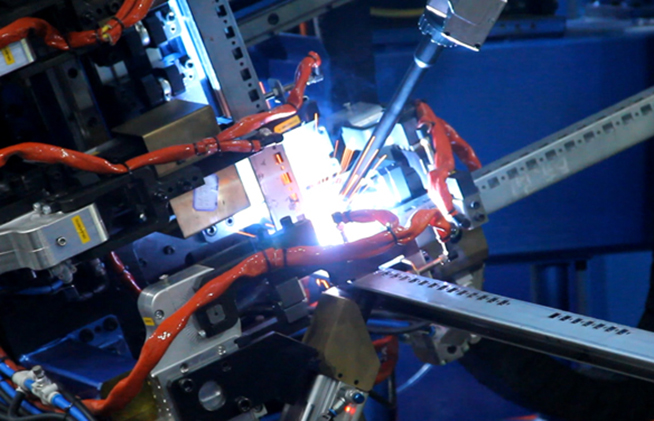

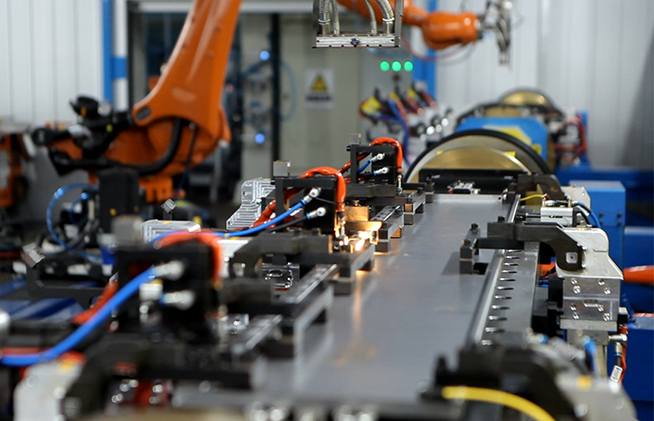

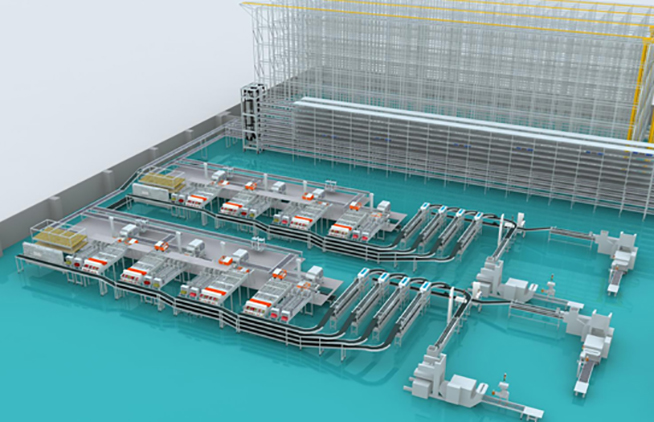

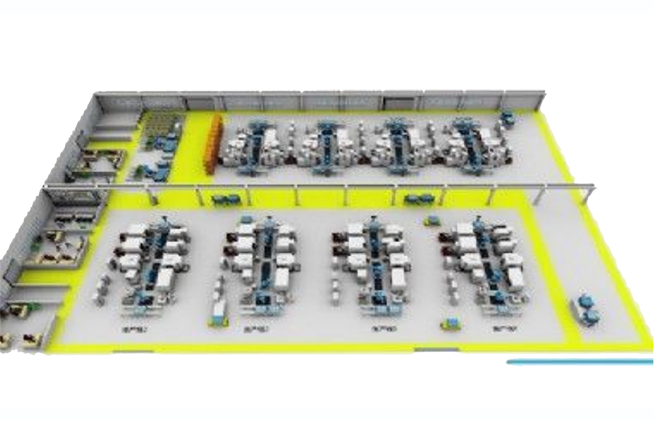

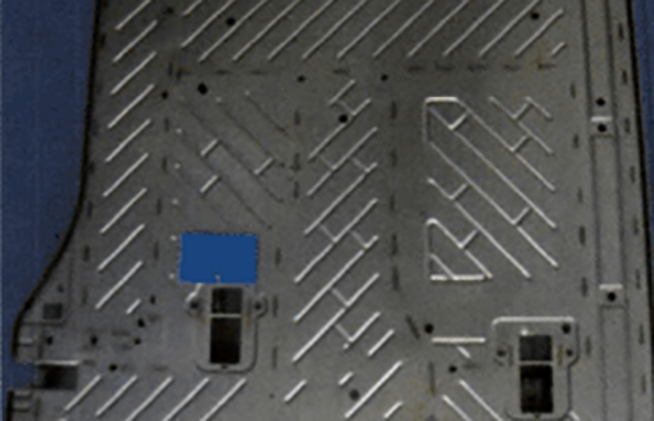

JGH30 steel bar truss production line

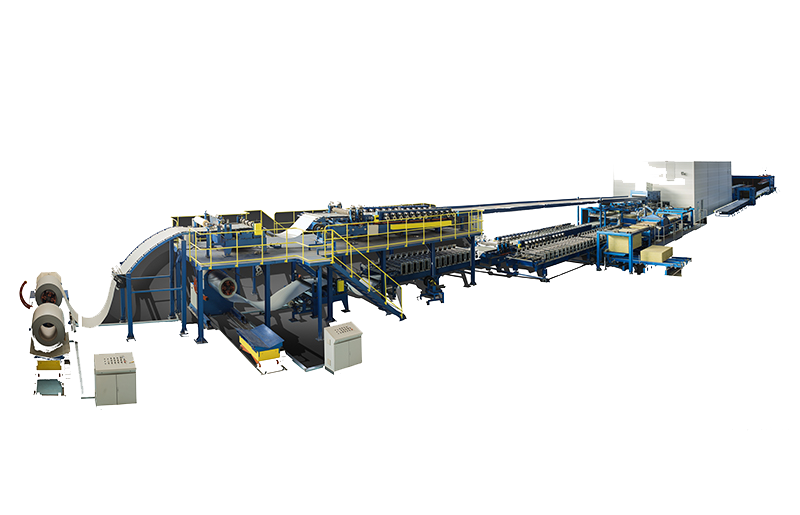

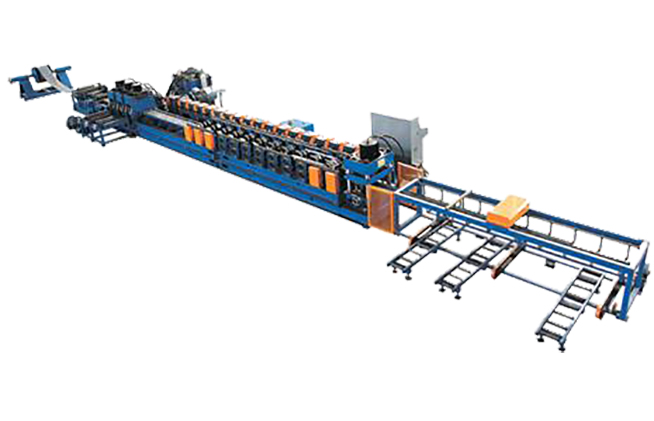

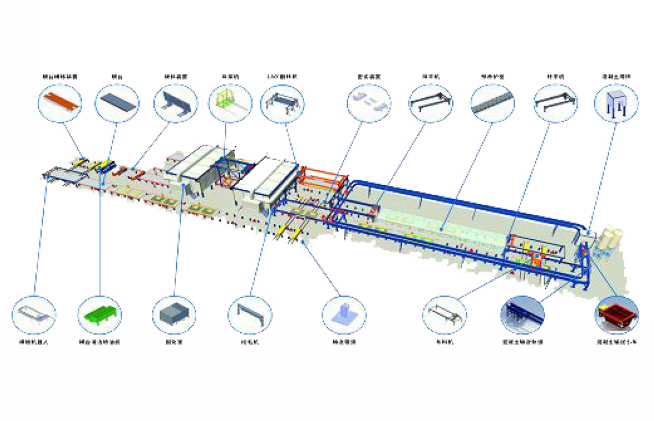

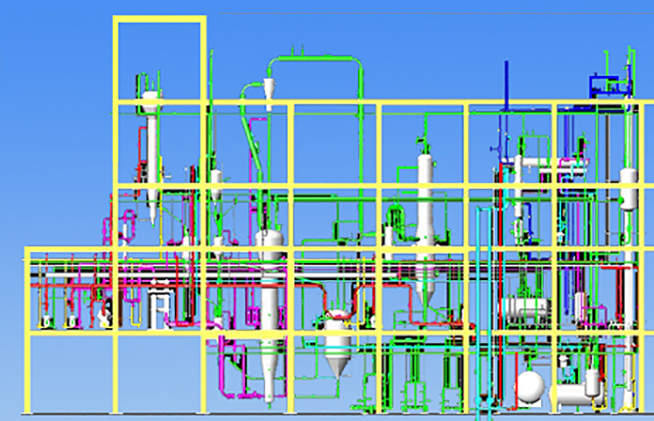

JGH self-supported steel deck whole set production line self-developed by Zhejiang Jinggong Science&Technology Co.,Ltd consists of truss welding line, bottom panel forming machine and board spot welding machine, combining mechanism, electricity, hydraulic and pneumatics with microcomputer control, it performs whole set production process of steel moulding board’s truss, galvanized steel forming and assembling&welding. The line’s annual single-round production capacity reaches 300000 square meters.