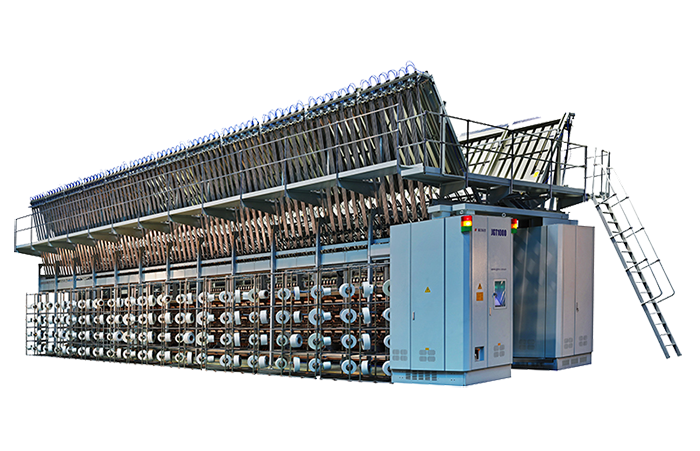

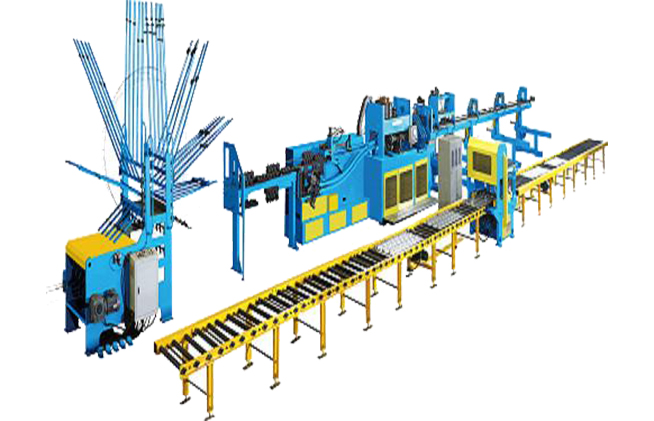

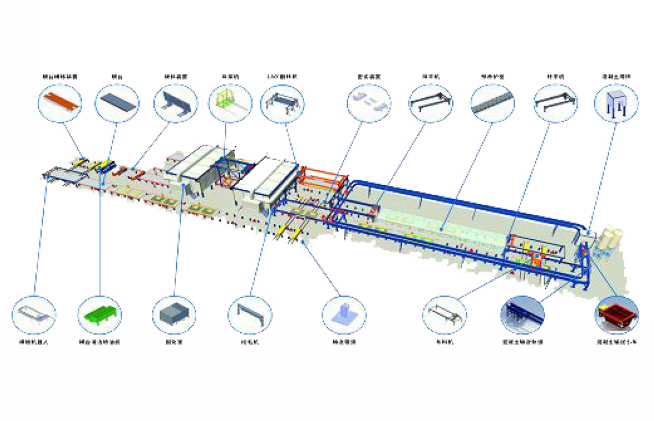

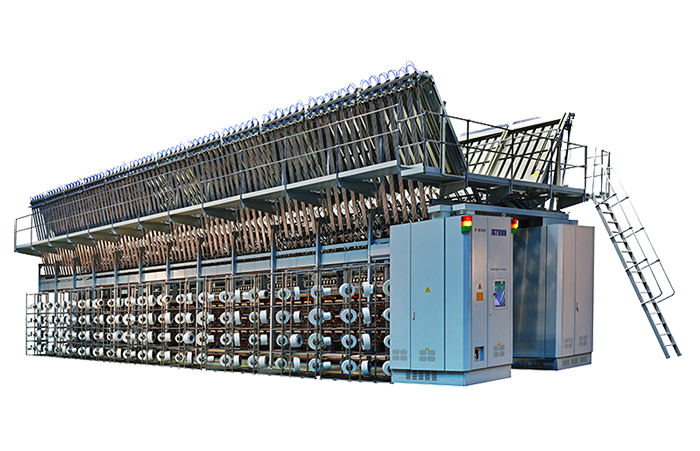

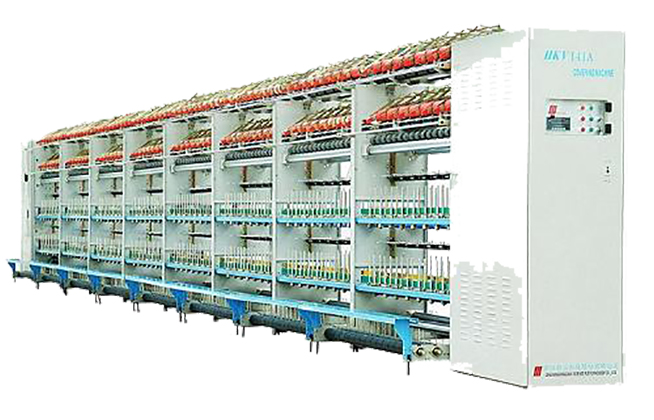

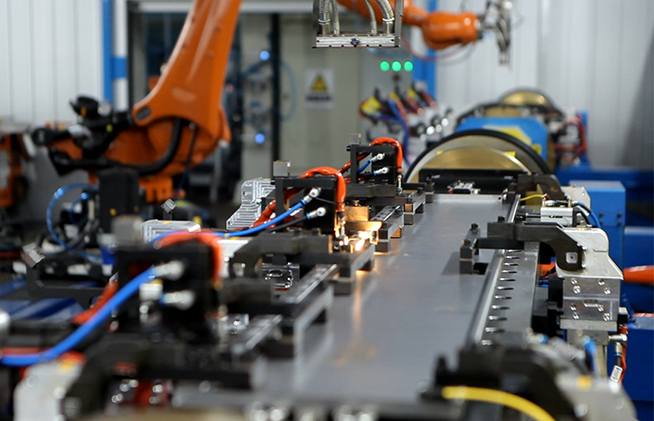

1、Equipment Overview

This machine mainly use is the POY yarn ( polyester silk) is through stretching and false twisting deformation, processed into low elastic or high elastic deformation of the false twisting silk(DTY stretch yarn), The equipment can be option to add the network components, so it can undertake network yarn processing.

2、 equipment performance and characteristics of main components

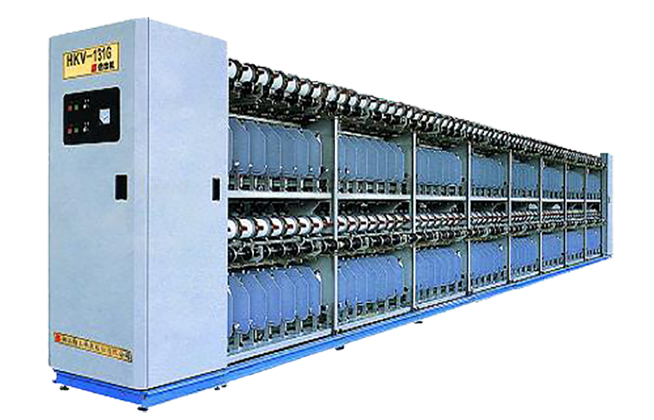

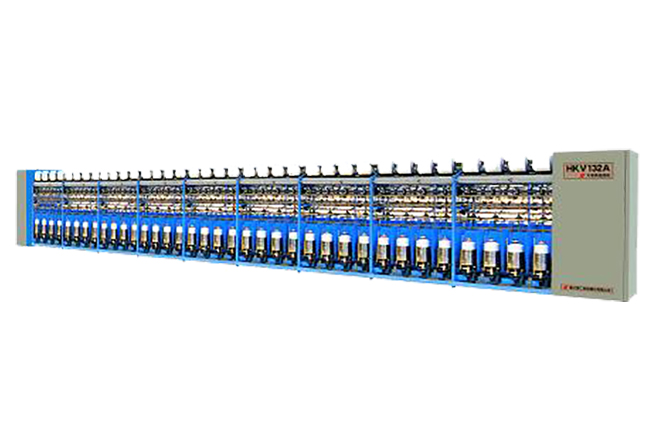

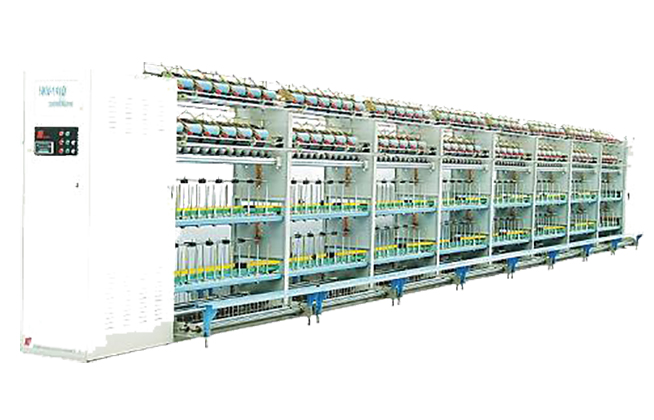

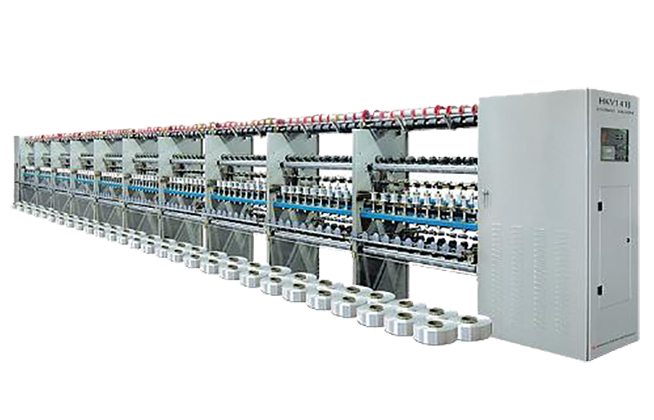

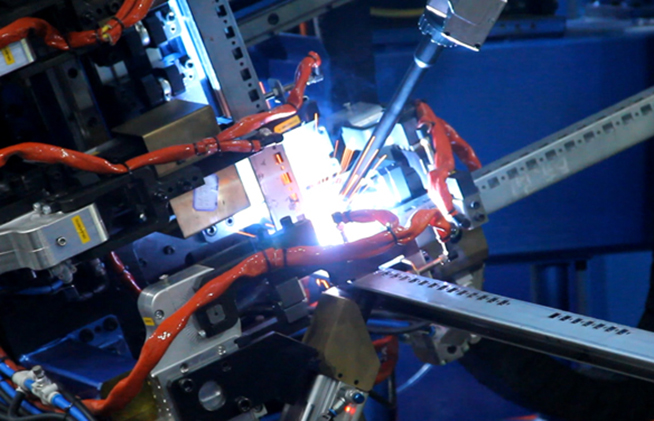

New hot box (the first heat box) on the structural arrangement, operating level is low, the silk road layout is more reasonable, the first heat box ( deformation hot box) and the second heat box ( finalize the hot box ) adopt biphenyl gas heating method, also has the function of over temperature alarm cut the original silk.

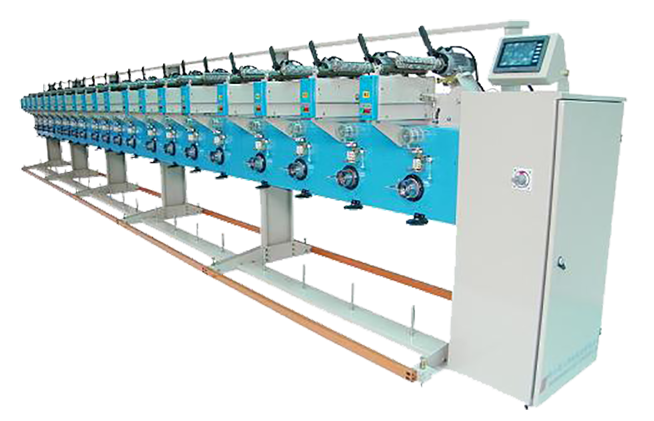

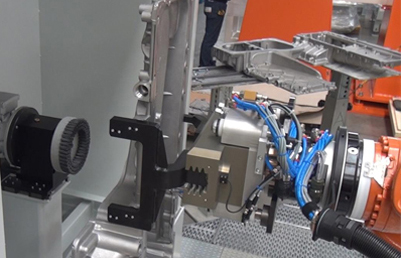

Using single axis motor direct driving, reduced the transmission chain, process more convenient adjustment, easy maintenance.

The stacked disc of VII type false twister, with both A/B sides of the independent belt drive, install ceramic import and knife-edge Export disk configuration range from1-4-1to 1-7-1 optional.

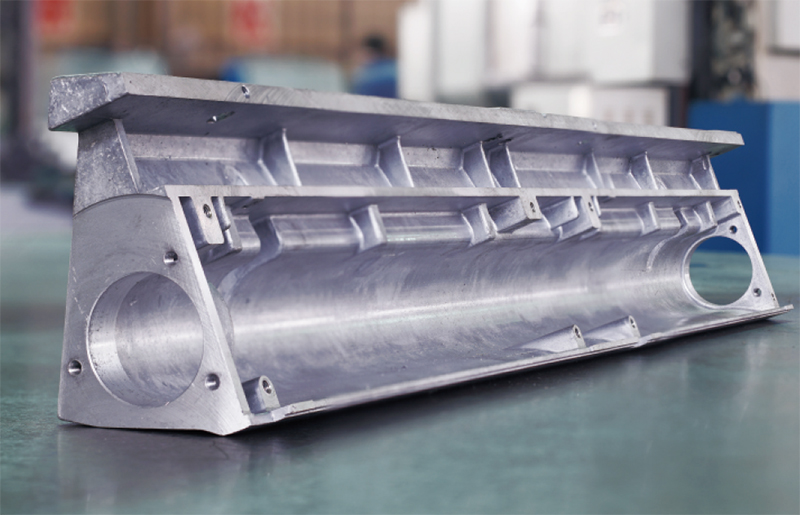

W1/W2,W3 roller adopt apron type structure, aluminum alloy frame aprons.

There are two strands for users to choose, both stationary and rotating.

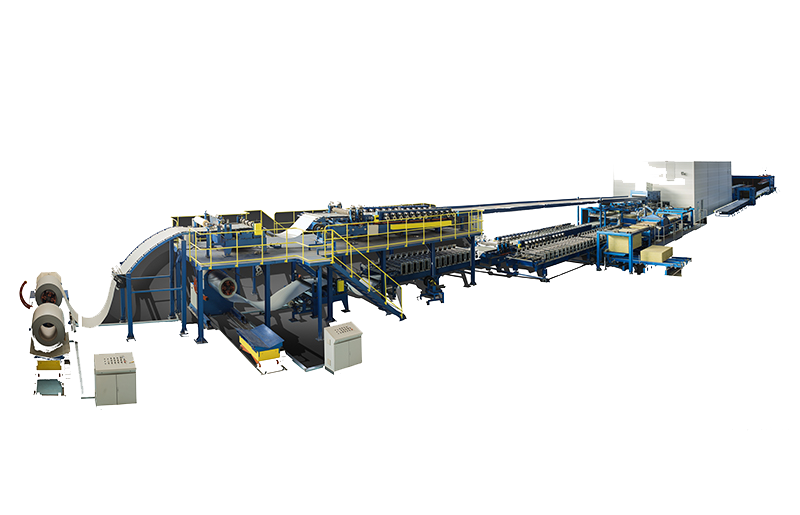

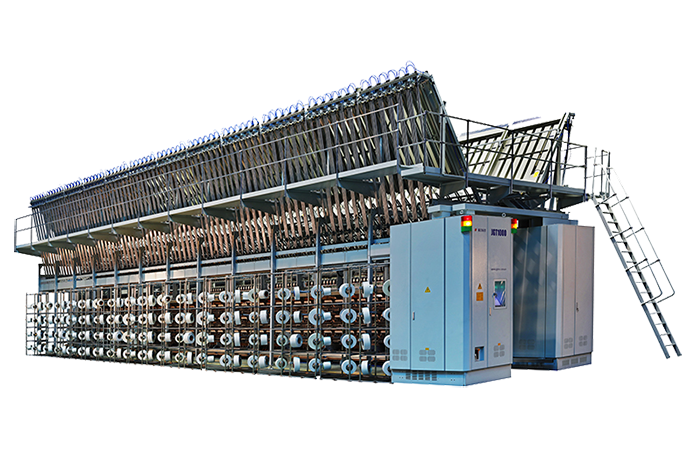

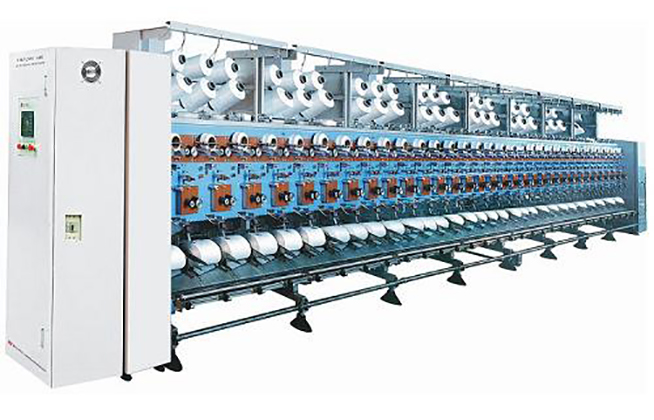

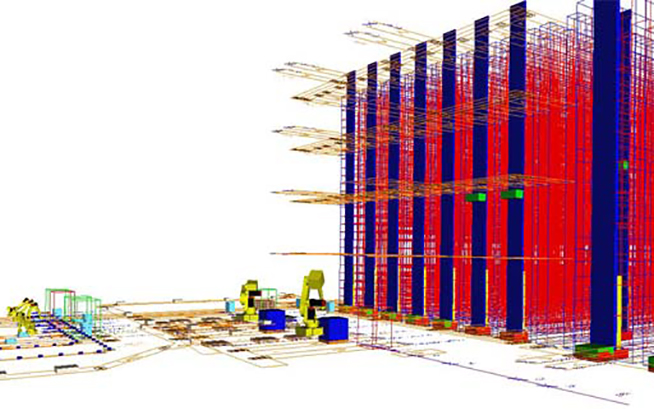

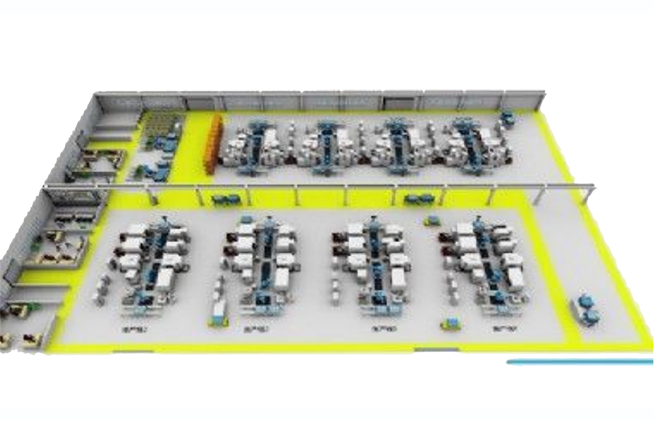

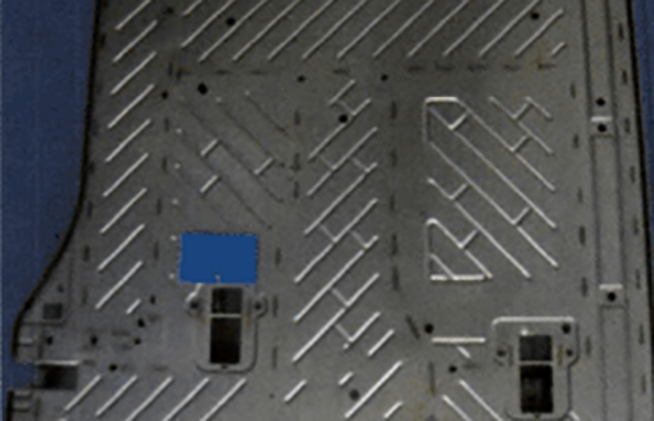

3、 Dimension drawing

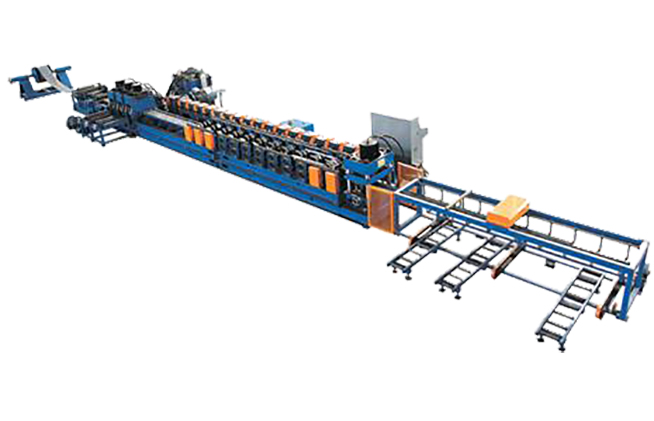

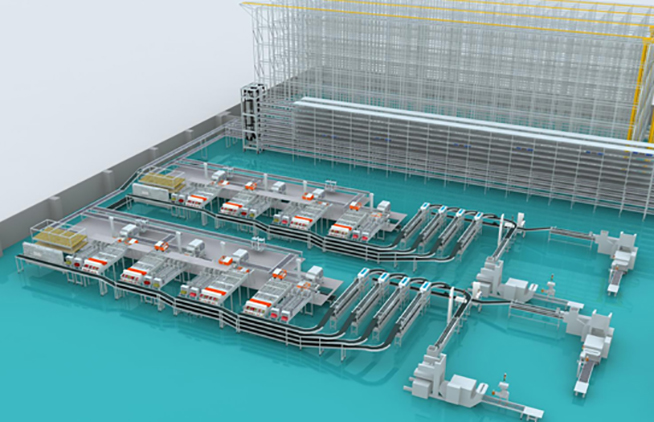

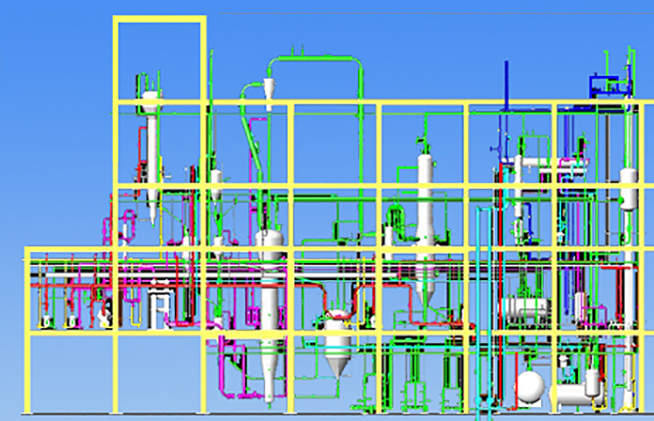

4、INSTALL THE ANCHOR FIGURE